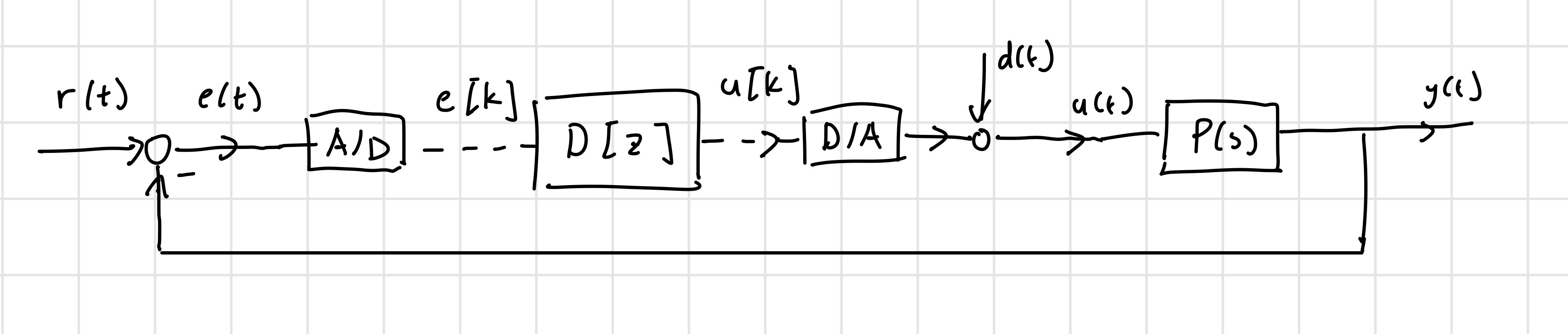

Because physical plants are always continuous-time systems, discrete-time control systems are in fact NOT digital control systems!

A sampled-data control systems uses a discrete controller, but is used with continuous input/output.

-

is our continuous-time plant

-

is our discrete-time controller

-

are all in continuous-time

-

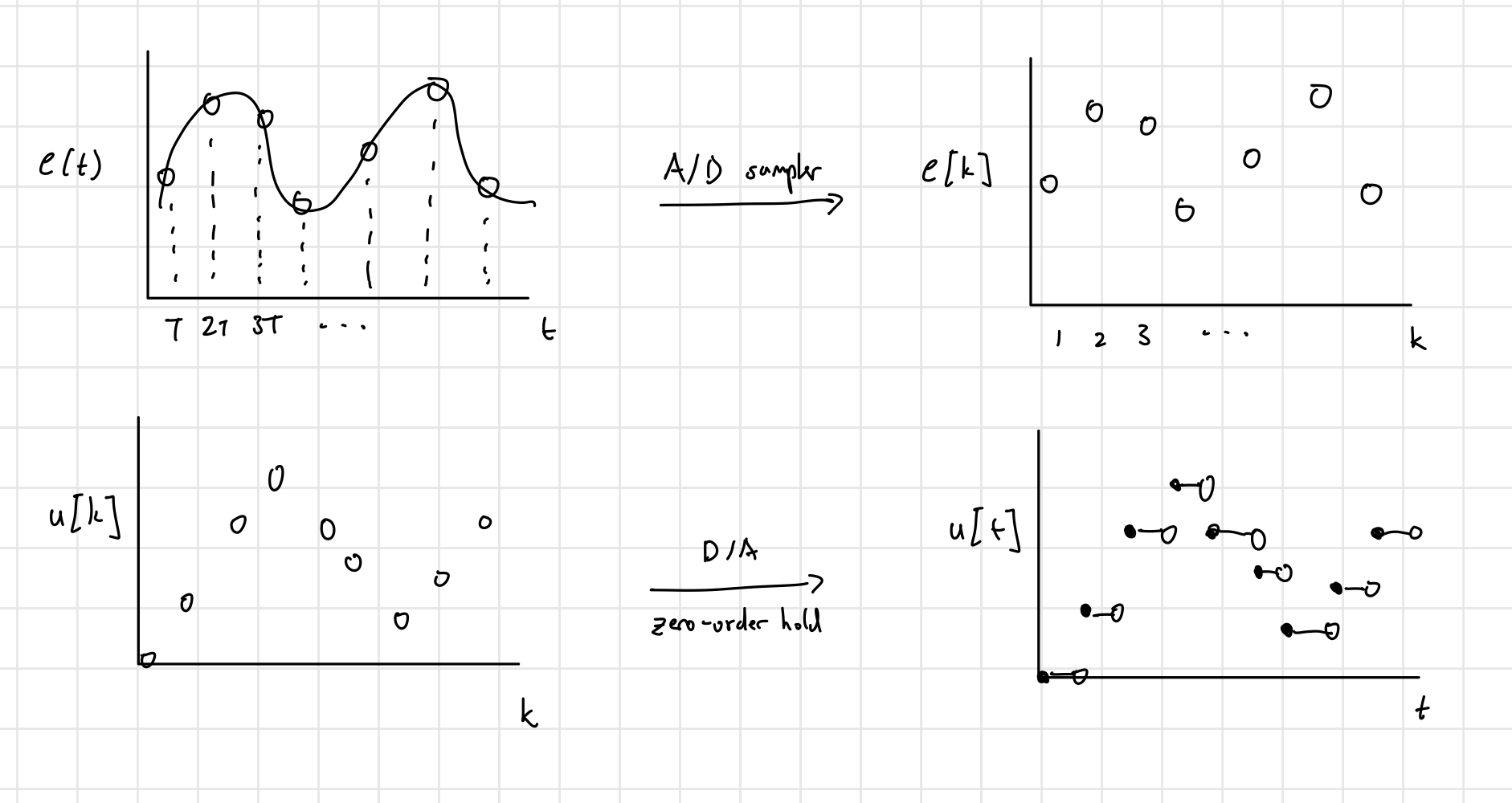

A/D is a analog-to-digital converter. It is a sampler that samples at discrete intervals, , where is the sampling time of the system

-

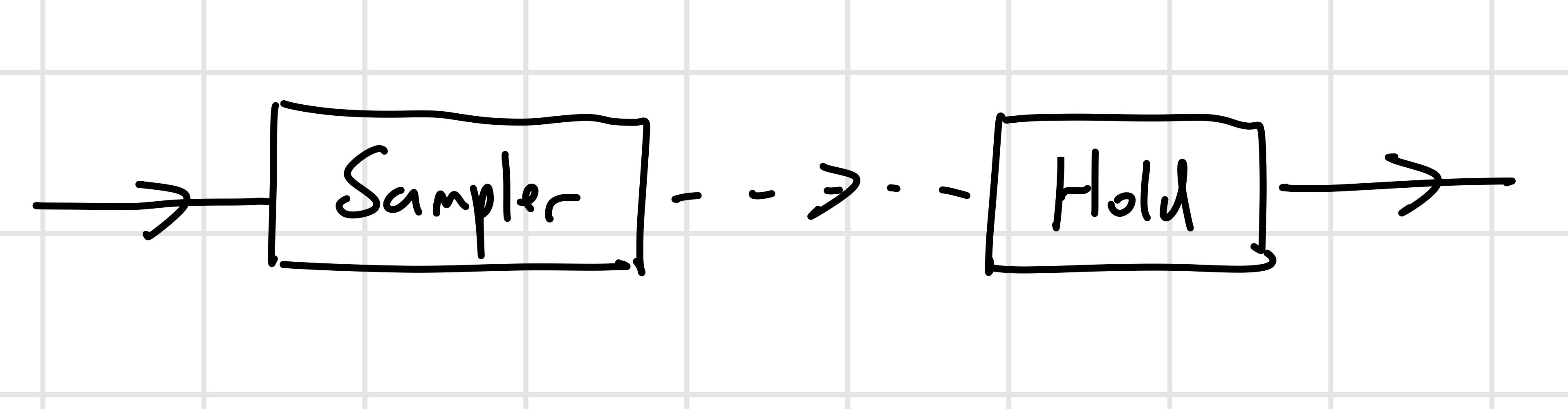

D/A is a digital-to-analog converter. Typically we use a “zero order hold” that holds for .

Theorem

Even a simple system that’s just sampler-to-hold (), the system is not LTI.

As a result, the full closed-loop sampled-data system is also NOT LTI.

Then what’s the value of studying LTI systems? Our approach:

- Attempt to choose (or modify our control architecture or control design) so that the sampled-data system is approximately LTI.

- Use LTI tools to perform control design.

- Approximating continuous-time controllers with discrete-time controllers (emulation)

- Direct design of discrete-time controllers.

- Analyze and simulate the results on the true system.

Examples

- . (Using continuous-time tools, one can show that this is stable as a closed-loop system.)

- .

We will look at two cases:

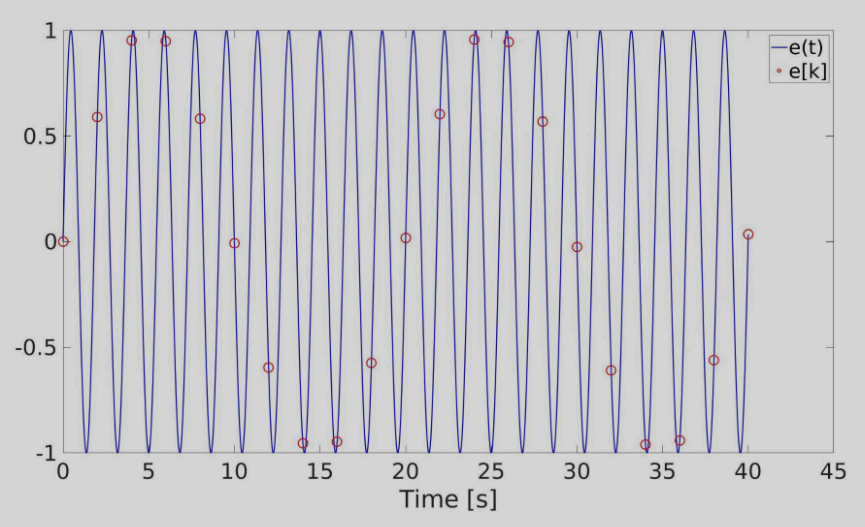

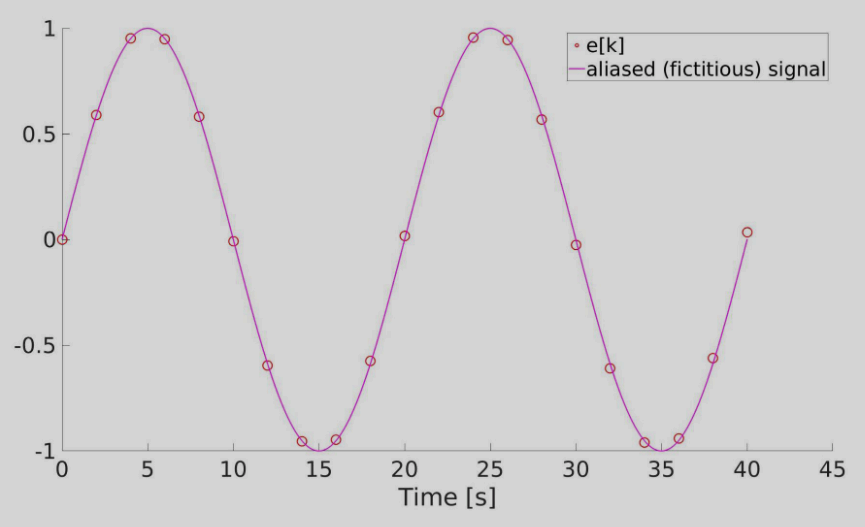

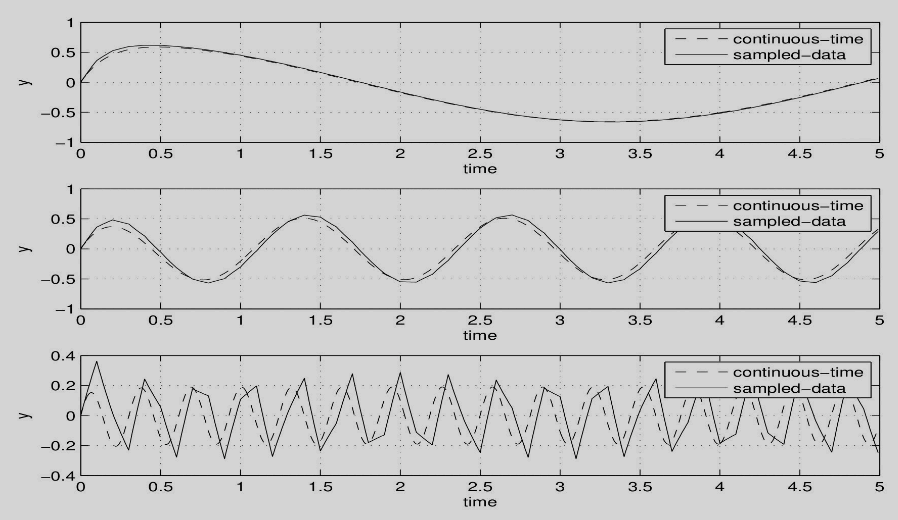

- Response to sinusoidal inputs: , :

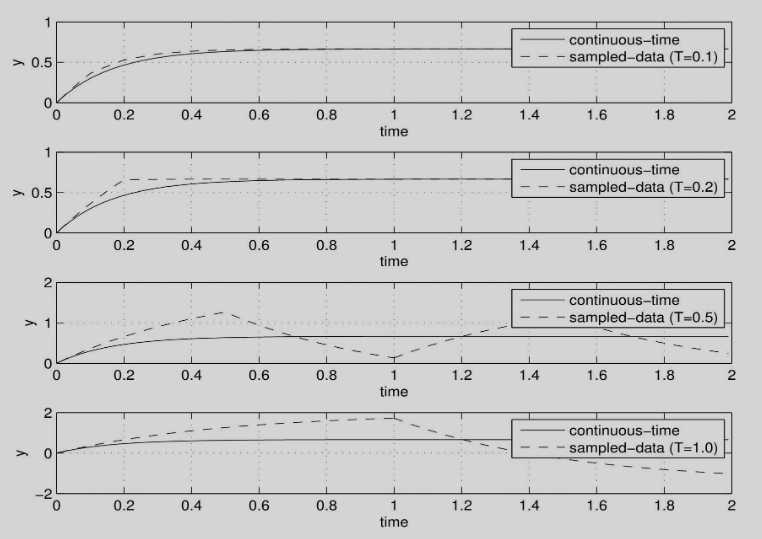

- Response to step systems: , vary sampling time

Sampling time aliasing

What happens when sample time is too large - we might end up with a fictitious (aliased) signal that isn’t representative of the real signal.