General Rules for Bearing Arrangement

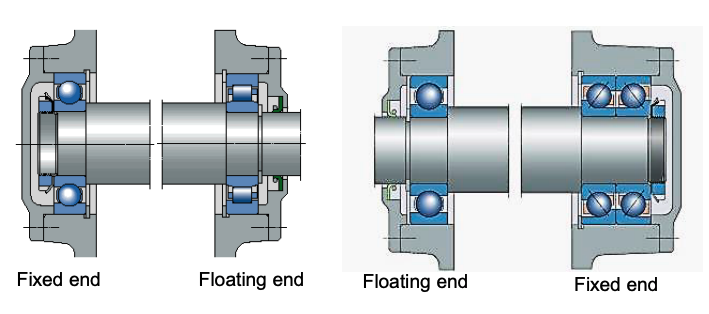

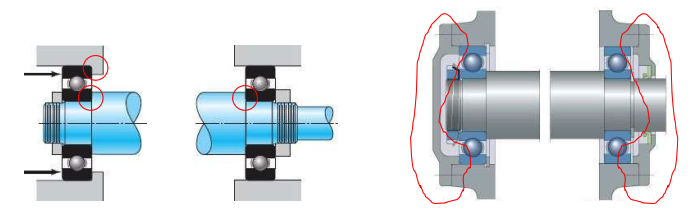

Fixed vs. Floating Bearings

A shaft is supported at least by two bearings, which are usually arranged in different ways:

- One is designated as a “fixed” bearing

- The other is designated as a floating bearing.

Floating bearing is the one that is left unconstrained axially, to accommodate for thermal (or other) expansion of the shaft.

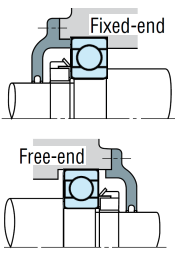

For non-separable bearings:

- Fixed-end: Constrain all four corners

- Free-end: Leave both sides open for inner ring or outer ring (but not both)

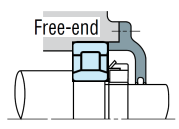

For separable bearings:

- Cannot be made fixed-end

- Free-end by default, so we can constrain all four corners

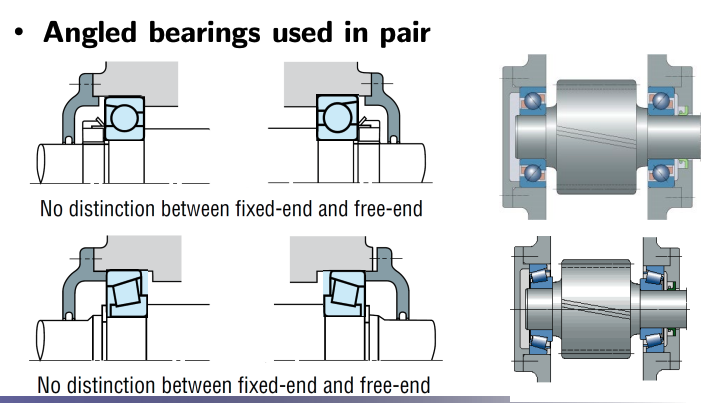

For angled bearings in a pair, there is no distinction between fixed and floating bearings.

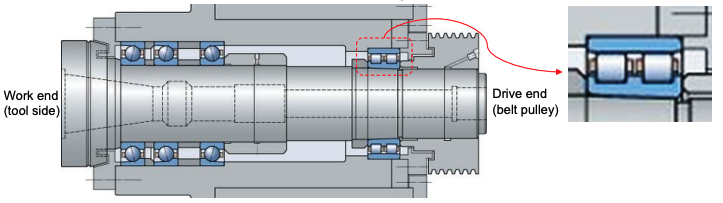

Whenever appropriate, bearings are arranged with one as fixed-end and the other as free-end. Usually, the working end is fixed and the driving end is free. If the shaft is short and thick, and no significant axial load, then we may not use free-end.

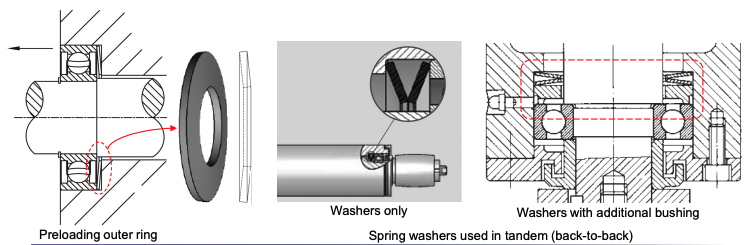

Precision Needed for Free-End

If the machine requires more precision, free-end may be constrained with Bellville spring washers. Bearing still allowed axially, but with some loads. Such preloading also reduces noise and vibration.

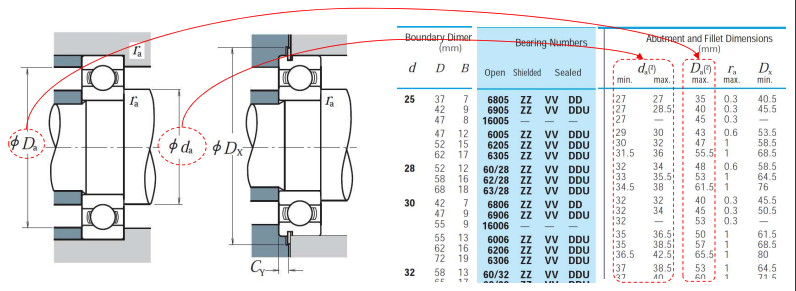

Abutment for Constraining Corners

To constrain each corner of a bearing, we should follow guidelines from the bearing manufacturer. All dimensions are specified in the catalogue.

Mountings and Enclosures

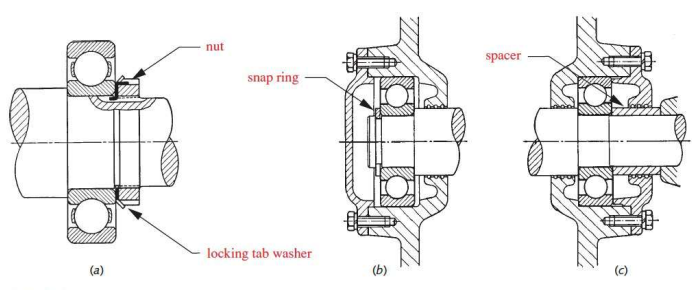

Common ways to fix bearing locations:

- Steps on shaft and/or housing are used if possible

- Housing cover is often used to fix the outer ring

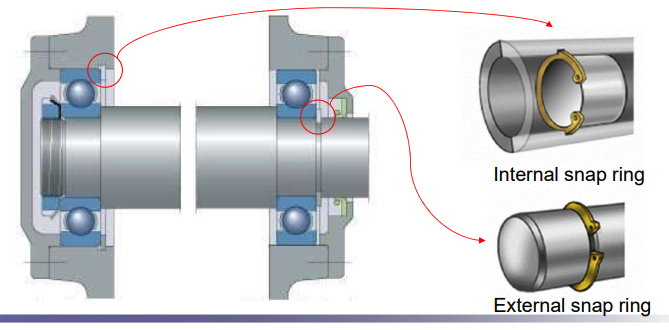

Other common ways to fix bearing locations:

- Locknuts, snap rings and spaces (bushings).

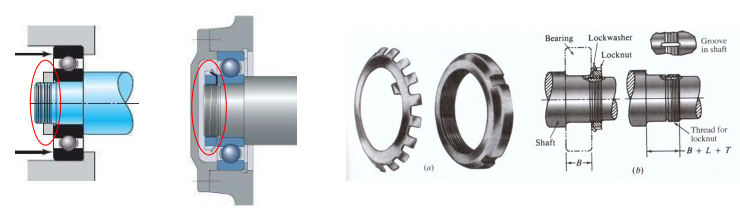

Locknuts and washers to fix bearing locations:

- For shaft, locknut and lock washer are often used when the axial loads are significant

- Machine threads need to be cut on shaft

Snap rings are often used for smaller axial loads.

In general, the choice of mounting varies by designer and may be driven by diverse factors.