Maximum-shear-stress theory predicts that yielding begins whenever the maximum shear stress in any element equals or exceeds the maximum shear stress in a tension-test specimen of the same material when that specimen begins to yield. Also known as Tresca stress.

In general, MSS is a conservative predictor of failure; the predicted yield strength in shear is about 15% lower than actuality.

3D Stress

Recall that for 3D stress we have 3 principal stresses :

and 3 principal shears:

For plane stress, the stress-free surface will have one of the principal stresses equal zero.

General Case

For a general state of stress, MSS predicts yielding when

where is the yield strength, which is the stress at which a material begins to deform plastically. Naturally, this means that the yield strength in shear is given by:

which is about 15% lower than in actuality, as mentioned above.

We can also incorporate a factor of safety :

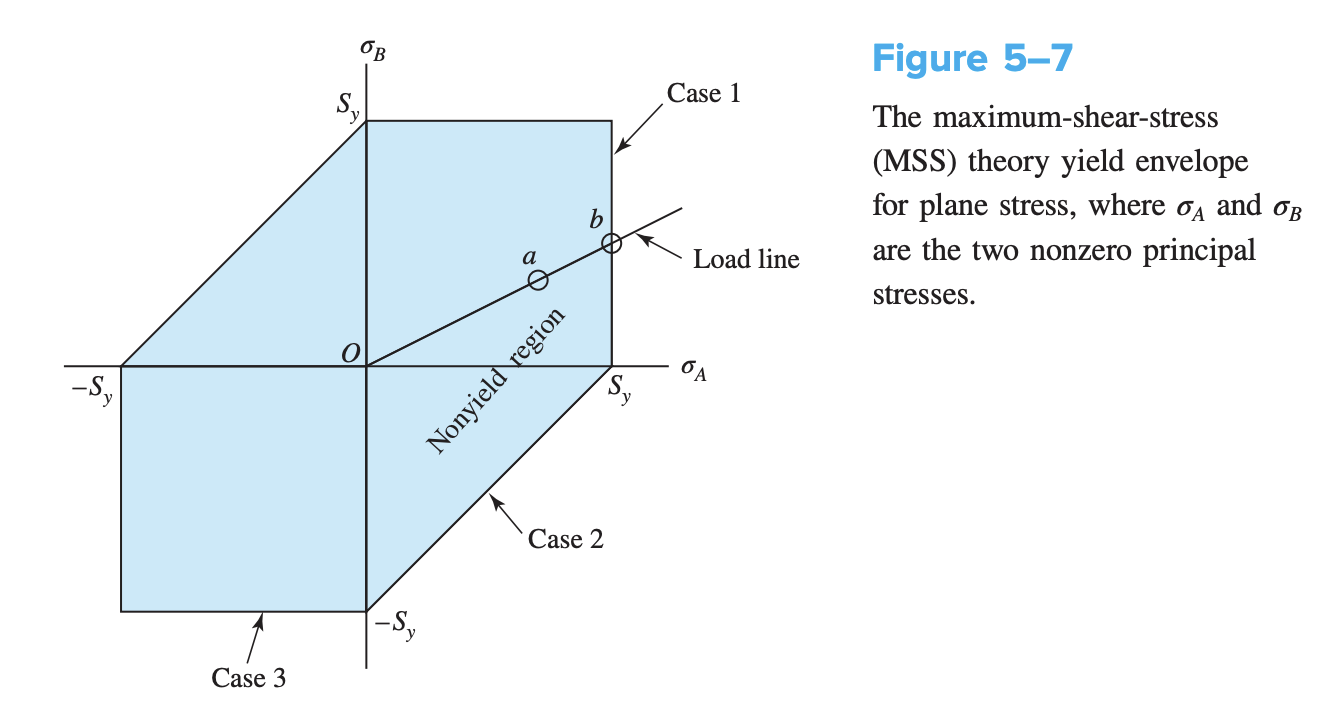

Plane Stress

In plane stress, we have two principal stresses in the plane stress, . The third principal stress is zero. Thus, there are 3 cases to consider:

| Case 1: | Case 2: | Case 3: | |

|---|---|---|---|

| Yield | |||

| Design |