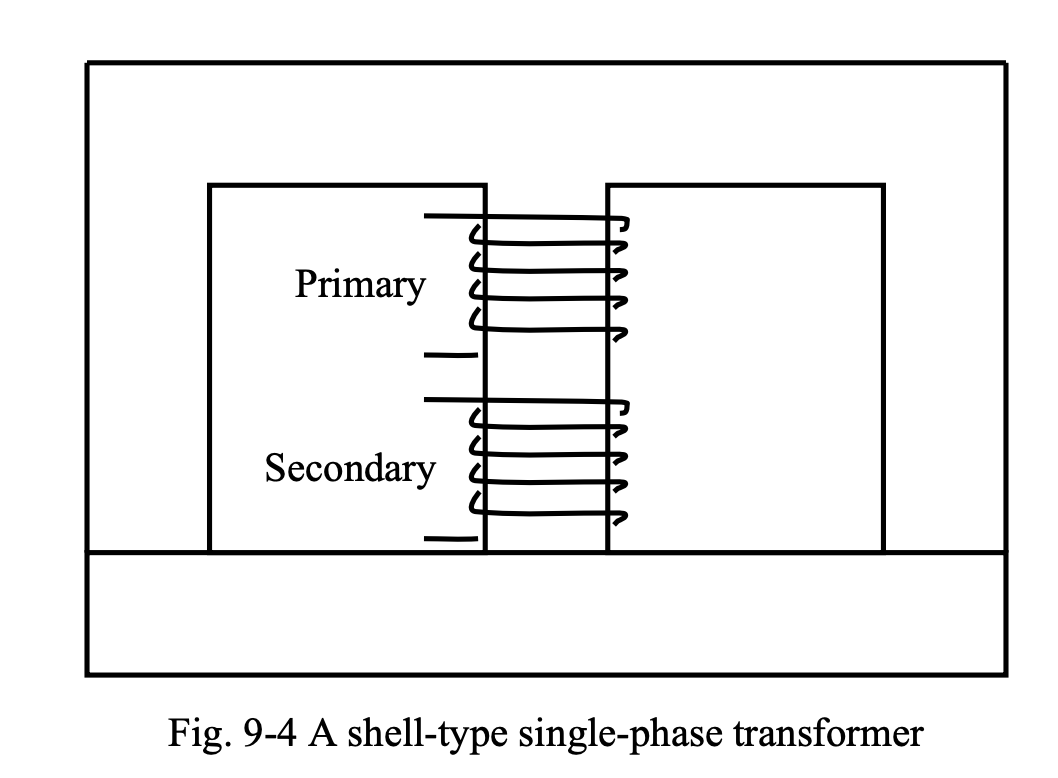

A shell-type transformer is constructed from a stack of E- and I-shaped laminations, which are interchanged from one layer to the next for mechanical integrity. The laminations are then clamped together to make a solid structure.

The primary and secondary windings are wound on the same leg of the core, as concentric windings, one of top of the other one. This results in a high flux linkage and small flux leakage. As a result, voltage regulation is improved compared to a core-type transformer.

The low-voltage winding is wound closer to the core, and the high-voltage winding is wound on top of the low-voltage winding. This is for insulation reasons.