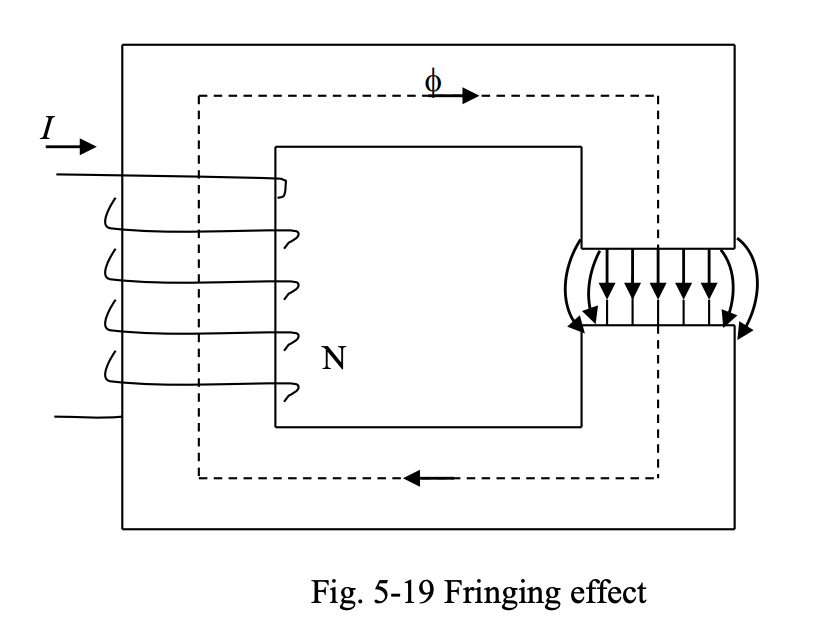

The effective area for the flow of lines of magnetic forces (flux) in an air gap is larger than the cross-sectional area of the core. This is due to a phenomenon known as fringing effect; since the flux in the core is the same as that in the air gap, the increase in the effective area causes a reduction in the magnetic flux density in the air gap.

Even though sometimes fringing effect and flux leakage are not considered in calculations for the sake of simplicity, these two phenomena are very important in the design of electric machines, where an air gap is inevitable, such that the loss of flux and reduction in flux density cannot be ignored. In electric machines, the length of the air gap between the stator and rotor is designed to be very small and the windings are placed in slots carved in the core to reduce the fringing effect and flux leakage.