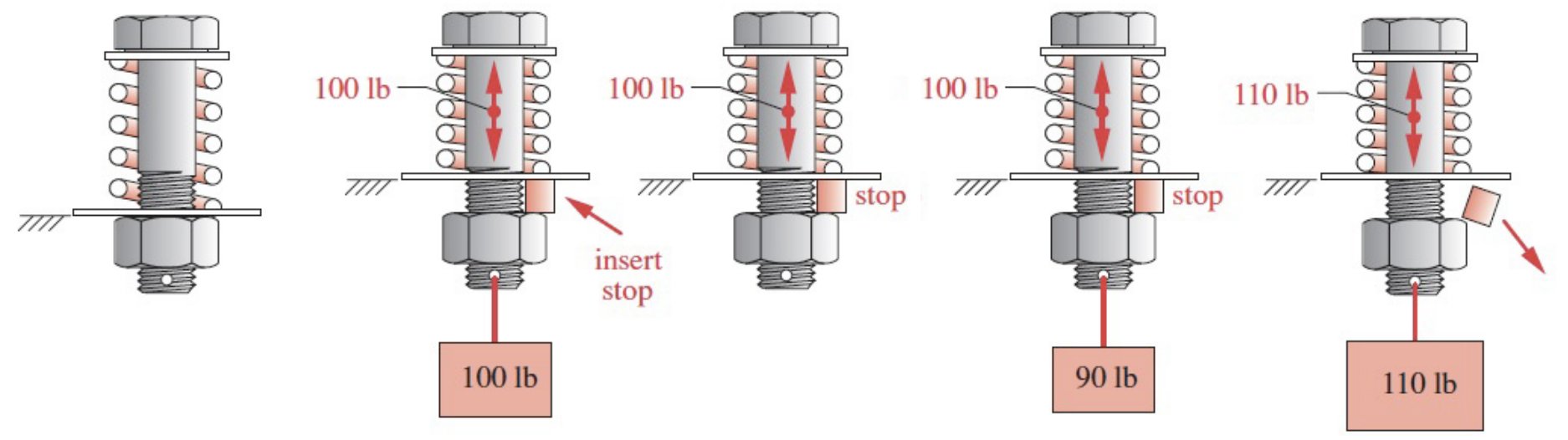

Pre-loading fasteners improves joint stability, reduces fatigue, and prevents separation under varying loads. Pre-loading ensures that the clamping force remains consistent, even when external forces act on the system. This is shown below:

- Initial state

- Fasteners is pre-loaded with clamping force of 100 lb. The preload compresses the joint members and ensures that the spring (representing the elasticity of the joint) is engaged. An external load (100 lb) is applied. Due to preloading, the fastener absorbs this force elastically without any joint separation. The preload ensures the fastener remains in tension while maintaining joint stability

- By inserting a stop to limit the compression or stretch of the spring, the system gains additional support. This prevents excessive movement under loading conditions.

- Even when the external load decreases (e.g., to 90 lb) or increases (to 110 lb), the preload remains effective. This minimizes joint separation and ensures the fastener does not bear the full brunt of the fluctuating forces, distributing stresses more uniformly.

How much pre-loading is desirable?

- Static loading: about 90% of proof strength

- Dynamic loading: about 75% of proof strength

Pre-loaded Bolts Under Static Loading

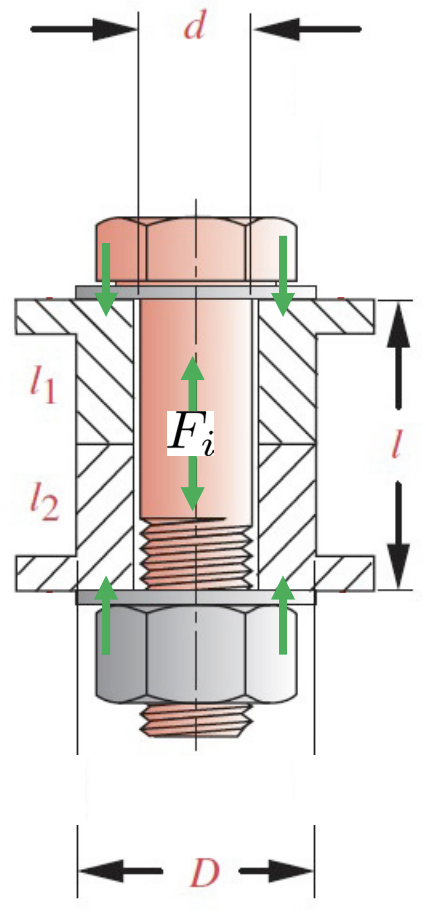

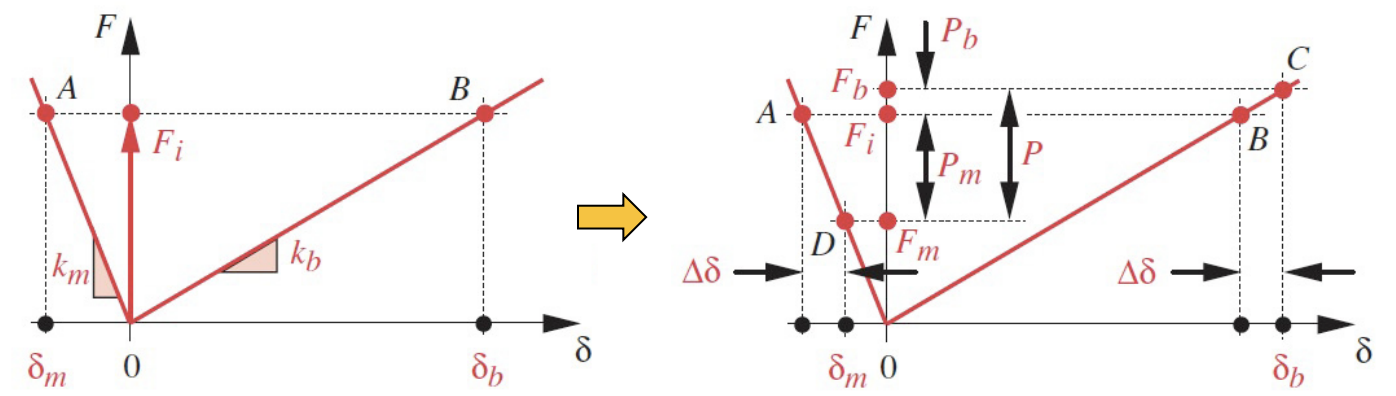

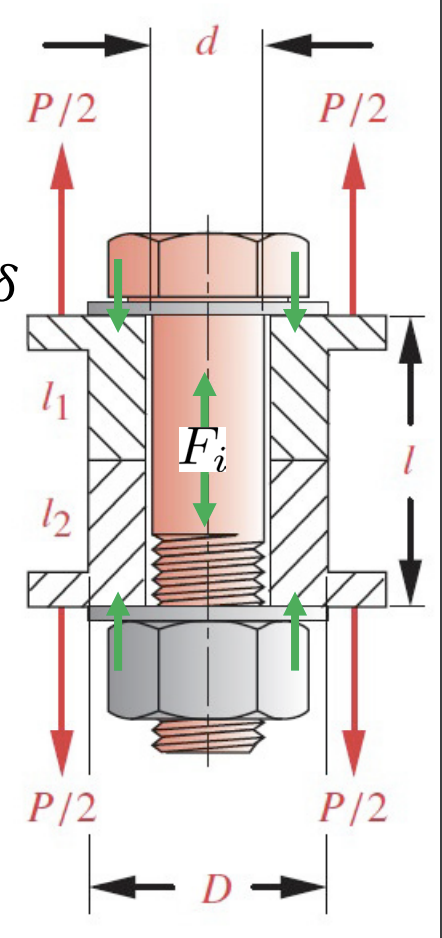

Assuming that we have a preload before the external load is applied. Then, we have:

- Load on bolt:

- Load on material:

- The bolt elongates by while the material gets compressed by . If , .

Now apply to material. will will be taken up by both material and bolt, i.e. :

- is external load taken up by the bolt

- is external load taken up by the material

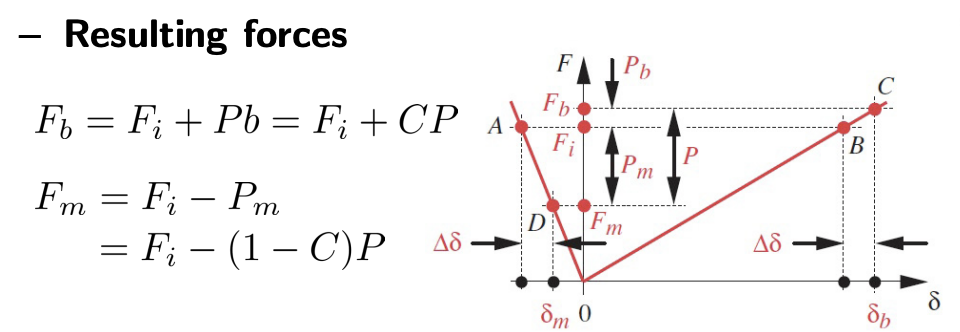

The total compressive load on material due to and :

Note that we want ; if , “separation” occurs.

The total tensile load on bolt due to and :

A compatibility condition: additional deflection due to the applied load must be the same for both the bolt and the material

Using , we get where is called joint constant.

Similarly, we get for the material.

Note, if (as is often the case), then and . Consequently, , which means that most of the external load will be taken up by the material.

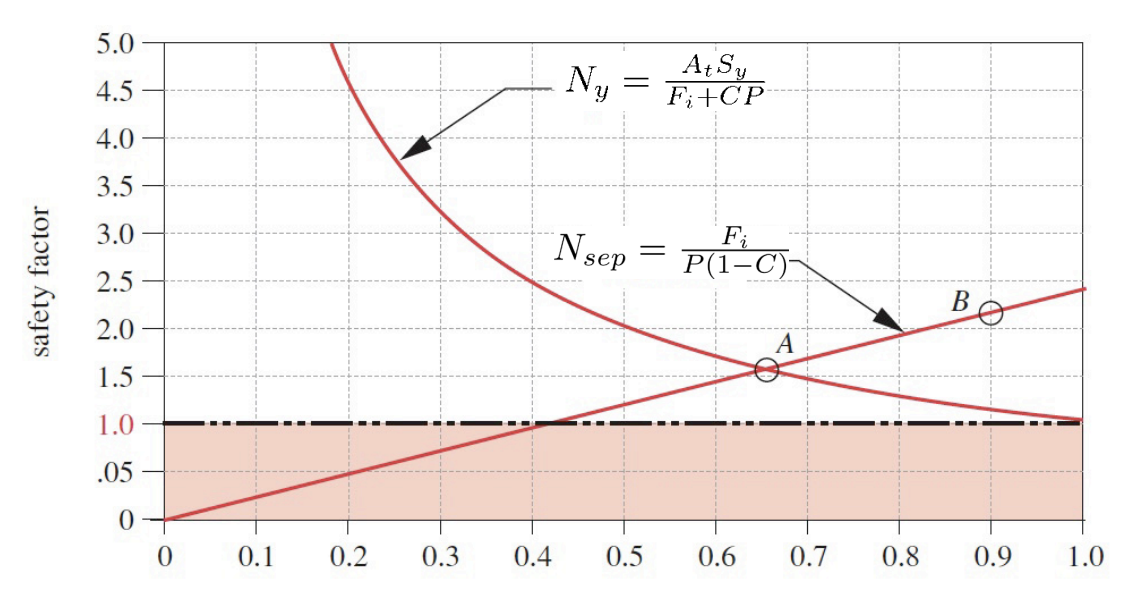

Safety Factors Related to Preloading

Safety factor against separation:

- Remember the material will separate (no clamping) when

Thus, the safety factor against separation is given by

Safety factor against yielding:

Load factor: overload capacity against proof strength

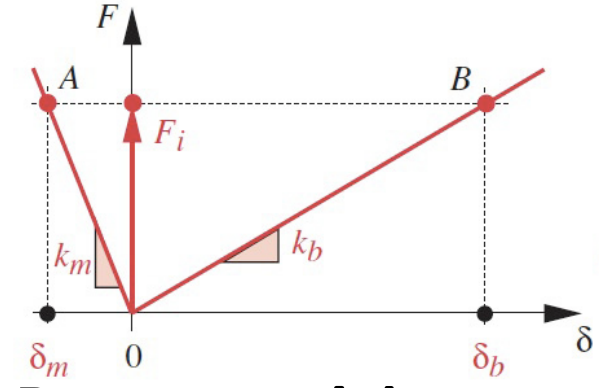

Determination of Pre-load

- Point A: Pre-load for

- Point B: Pre-load for protecting joint against possible overloads. 90% of proof strength.

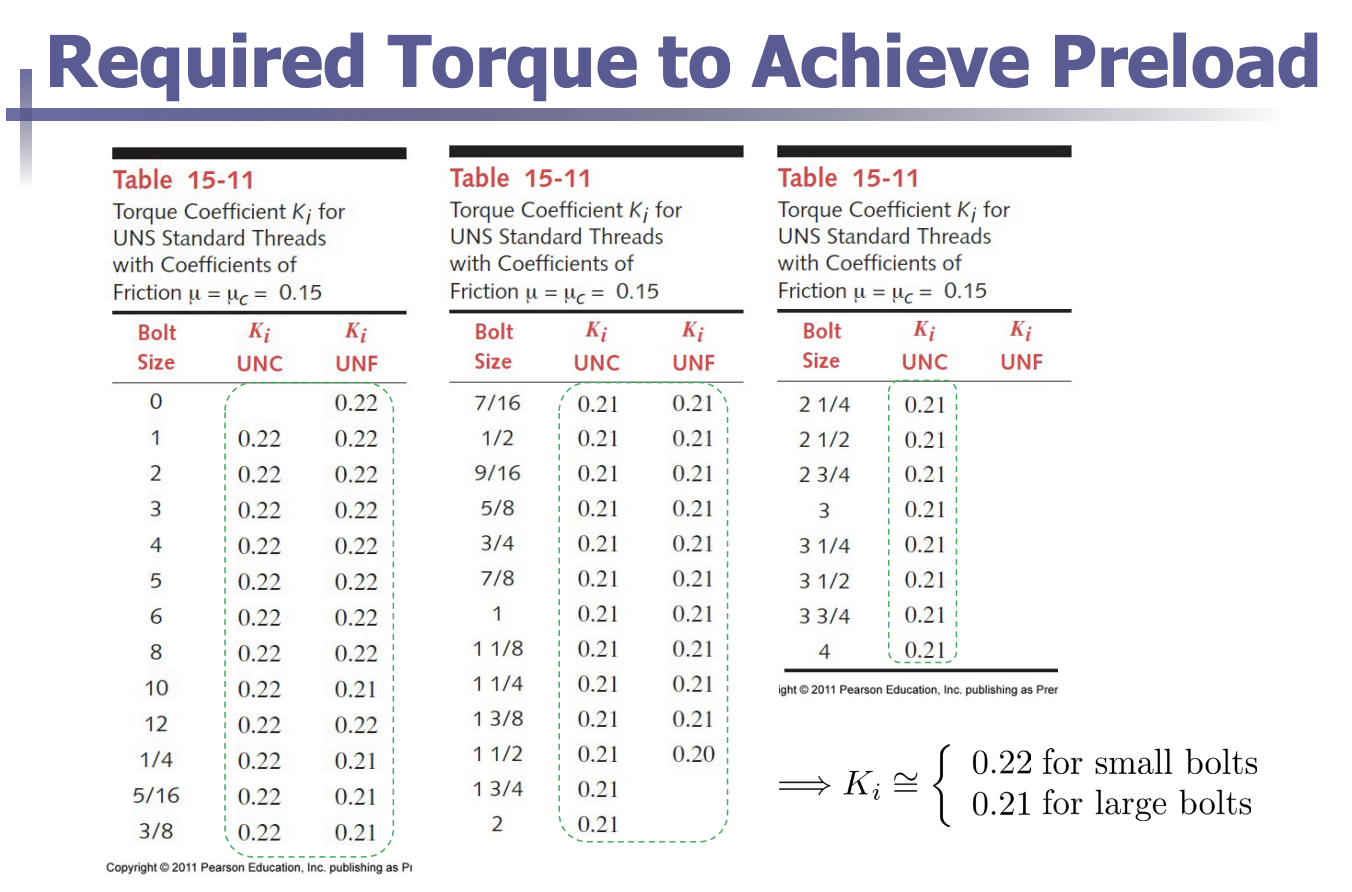

Required Torque to Achieve Preload

How to compute wrench torque required to develop the specified preload?

From the power screw, we have

Approximating , , we get

Assuming and using :

Interestingly, is similar for all threads. For example, for 3/8 - 16 UNC thread, , ,

Example

Example 7: Pre-loaded Bolt for Static Load

Properly Preloaded Bolt “Never” Breaks in Statically Loaded Service:

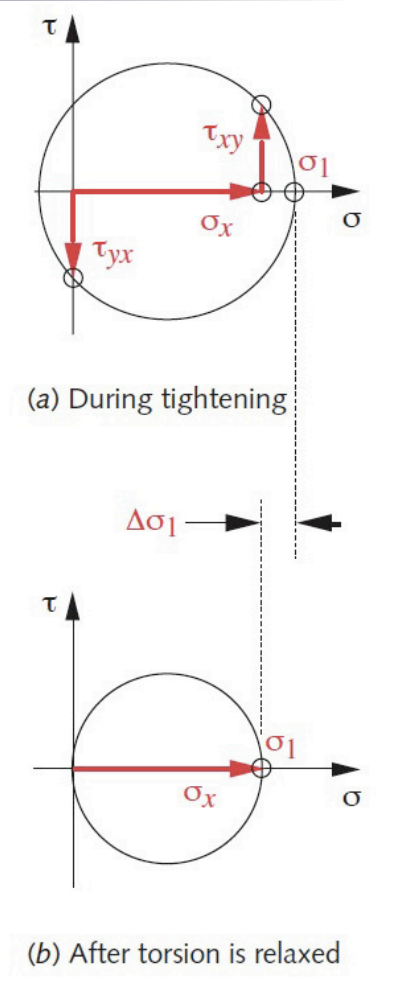

During preloading, the principle stress is determined by the combined effect of tensile and shear stresses

After preloading, the shear is gradually relieved and eventually, only the tensile component remains.

Thus, the principle stress long after preloading is smaller than that during preloading by the amount