Square Thread

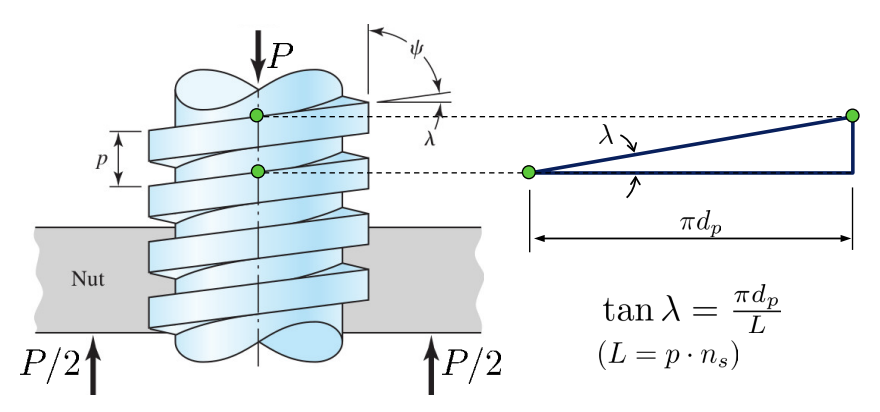

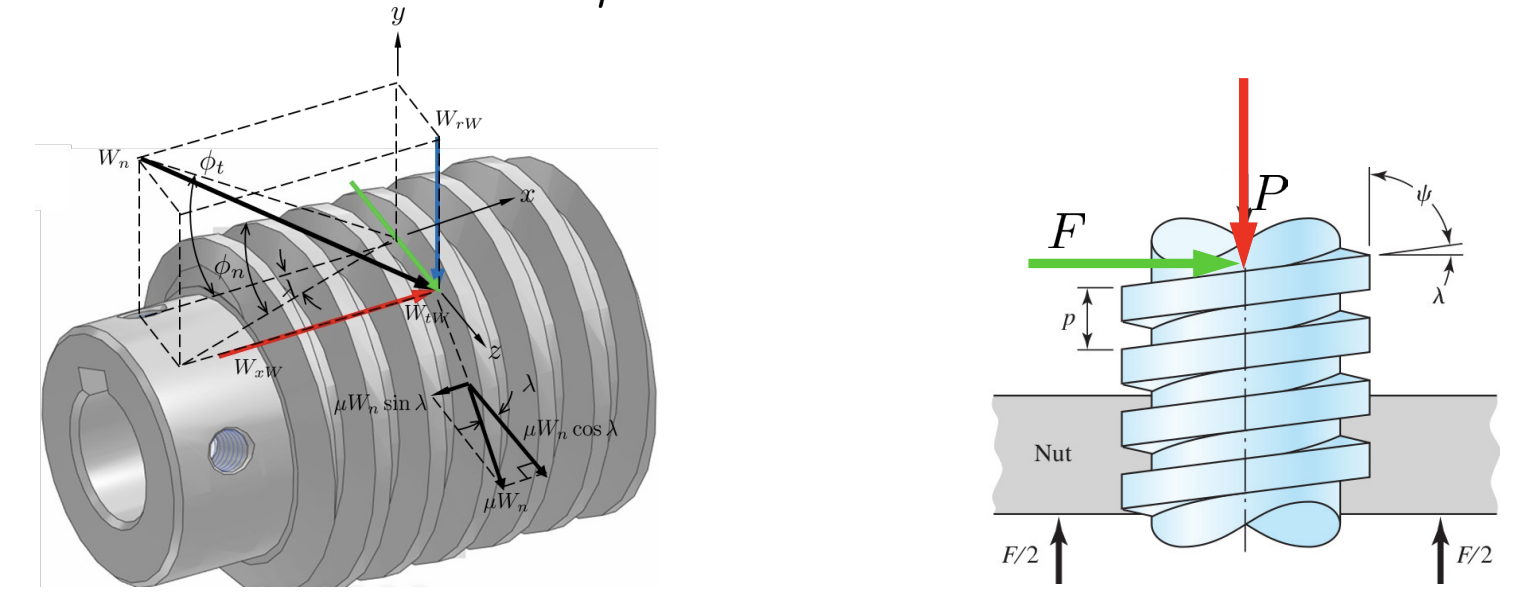

Imagine that a single thread of a power screw is unrolled for a turn:

- Note that , where .

Then, one edge of the thread will form the hypotenuse of a right triangle whose base is the circumference of the mean-thread-diameter circle and whose height is the lead. The angle is the lead angle of the thread. We represent the summation of all the axial forces acting upon the normal thread area by .

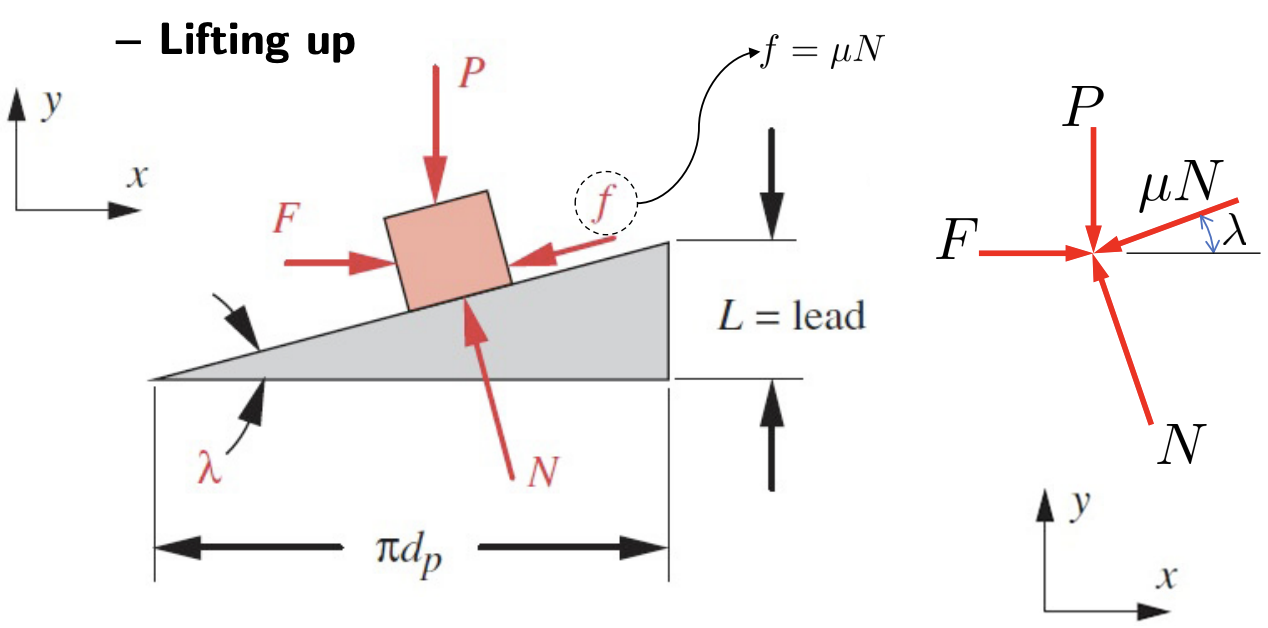

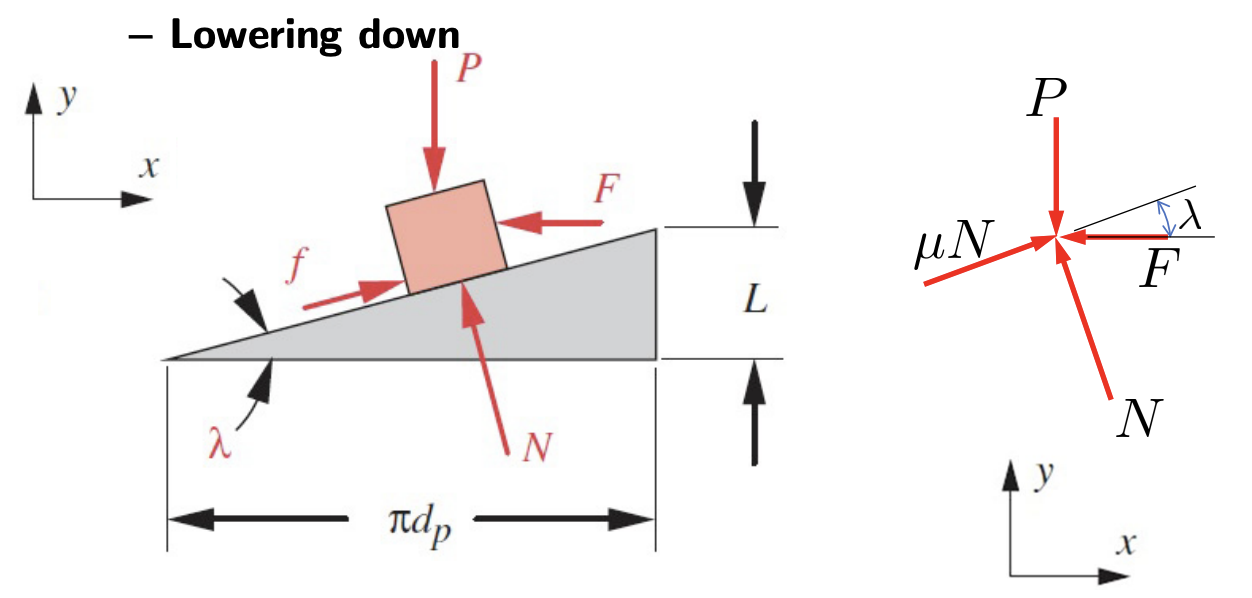

To raise the load, a force acts to the right. To lower the load, a force acts to the left. The friction force is the product of the coefficient of friction with the normal force , and acts to oppose the motion.

Force Analysis

We can conduct force analysis to find the required torque to resist linear load .

The first equation above gives

The second equation gives:

We can then write

When lifting up, we are work against the load, which gives us:

When lowering down, we work with the load, which gives us:

In practice, we must also deal with additional torque required to overcome the friction in the bearings of the system:

where . Here, is the coefficient of friction in the bearings, and is the diameter of the shaft.

If , the load is large enough to make the screw spin with no external torque. If , the screw is self-locking.

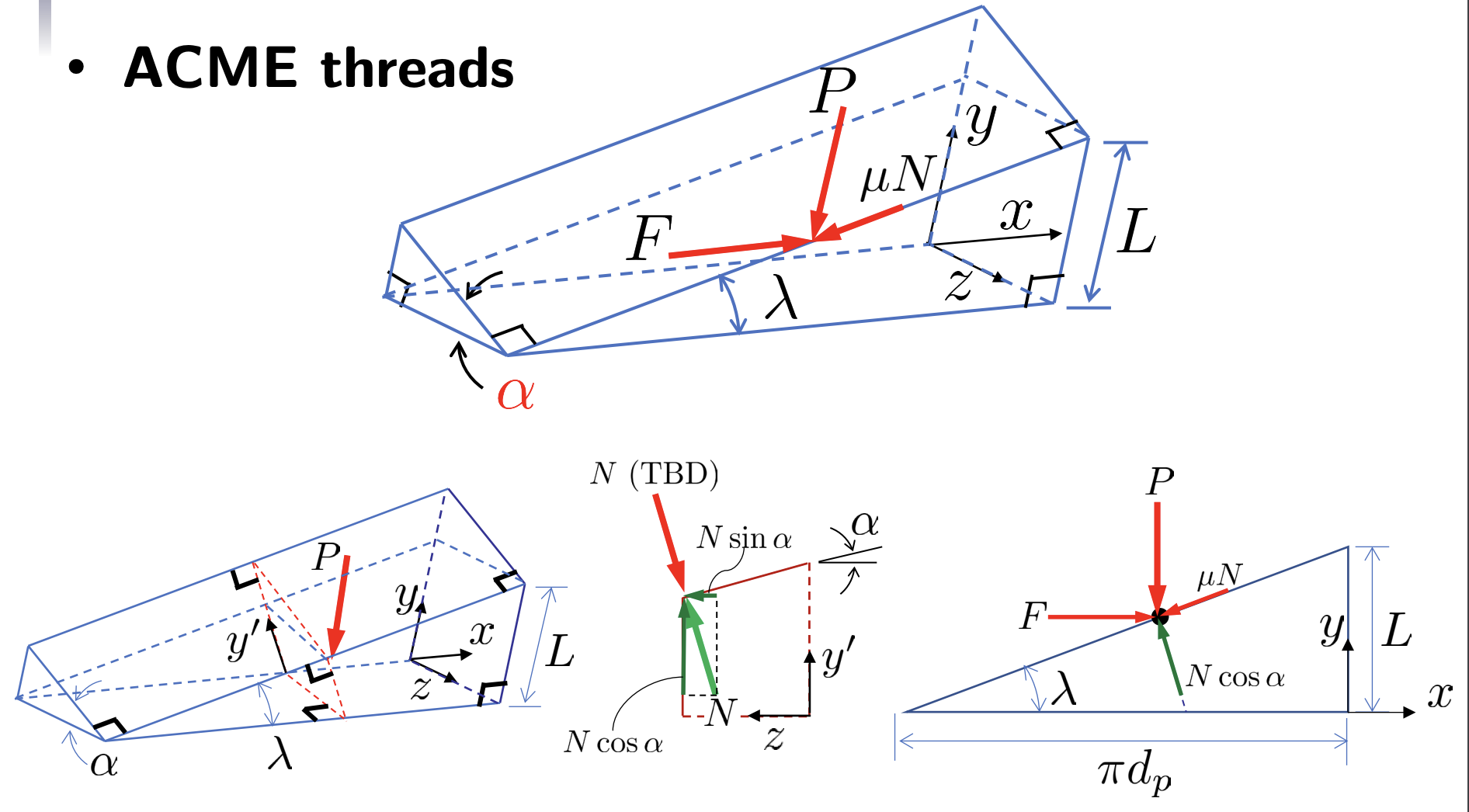

ACME Thread

\

\

Relation to Worm Gears

From worm gear load analysis, we derived

From power screws, we have just derived

Examples

Example 1: Power Screw Jack

Example 2: Scissor Jack